多光子聚合雷射共焦顯微鏡

- 產品說明 (點擊展開觀看)

-

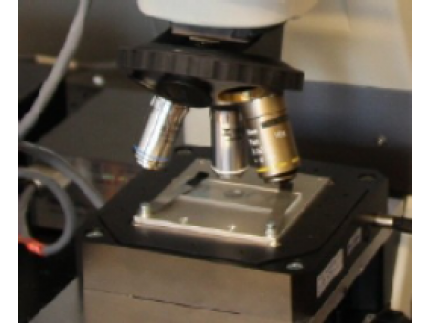

3D Microfabrication system

Nanofoot Finland Oy develops and manufactures 3D micro & nano fabrication systems, allowing for true 3D micro and nanostructures fabrication with feature sizes down to 100nm. The compact and flexible system allows for R&D investigations and technology implementations in the field of 3D fabrication. Simple design and construction of the system allows testing of wide range of commercially available materials for applications in the filed of photonics, life sciences and biology etc. Thanks to the system’s modular design and friendly user interface, different 3D structures and patterns can be produced with atmost ease.

Technology

Nanofoot’s technology for the fabrication of 3D micro and nanostructures is based on ”two photon polymerization (2PP)” technique i.e., a non-linear two-photon absorption process, where two photons are absorbed simultaneously. In the presence of ultrashort laser pulses molecules can simultaneously absorb two or more photons, which causes the material to polymerize at the focus point of the laser.

Main features

- Compact and flexible system with different laser options

- Picosecond laser : Compact, Cost effective and Reliable

- Femtosecond laser : Highly efficient, higher resolution and wider application range

- Highly modular system’s automation structure

- High resolution with precision accuracy

- Piezo- electric nano positioning stage

- Stepper motor stage

- Piezo (Z) nanofocusing stage

- Original Advanced 3D software

- Custom tailored original software, user friendly

- Dedicated to positioning and management of the system

Additional Options

- Different combinations based on customer requirements

- Fast 2D scanner option aslo avalable

- Real time camera observation of the process

Software

The key feature of the Nanofoot’s 3D fabrication system is the original software which is highly user friendly, intutive and designed to adapt to various drawing softwares and files. The software provides easy access and control to all adjustable features and components of the system. The user interface allows visualization of the structured data in 3 dimensional form and also real time monitoring of the area of the sample being processed by the laser.

Benefits

- Compact, easy to use and versatile

- Cost effective and reliable

- Highly modular and flexible

- Possibility to be used with different lasers

- Testing of wide range of materials (protiens, biopolymers, photoresists, modified ceramics)

- High resolution processing (<100nm)

- Advanced software enabling processing of 3D structures, patterns, complex shapes and contours

- Suitable for both industrial and laboratory R&D

Applications

Biomedical

- Tissue Engineering

Tissue Engineering is to culture cells in vitro on a 3D scaffold and implant it inside the body of an individual where it grows and perform repair action. One of the most popular approaches in tissue engineering is the use of 3D scaffolds whose function is to guide and support cell proliferation in 3D. Scaffolds fabricated by the 2PP technique will enable systematic studies of cell proliferation, acquired functionality, and tissue formation in 3D.

- Remove cells from the body (stem cells/ functionally differentiated cells)

- Cell expansion in culture

- Seed the cultured cells on 3D scaffolds in culture media supplemented with growth factors.

- Leave in culture to form functional tissue.

- Re-implant the engineered cell-scaffold construct to the injury site for repair.

- Cell culture and cell growth studies

Scaffolds and cell culture cages fabricated by the 2PP technique will enable cell activation and differentiation studies to functionally dictinct subsets. Human embryonic stem cells (hESC) have a unique capacity to differentiate to any type of cell or tissue providing an enormous potential for therapeutic applications. To make tissue engineered implants e.g. for cartilage defects, human chondrocytes are cultivated on the scaffolds in cell culture labs outside the body. Later on the whole cell matrix construct is implanted to fill the tissue defect. As the cartilage tissue regenerates, the flock implants then start to degrade.

- Biomaterial research and Regenerative Medicine

2PP technique enables research and testing of biomaterials used as reconstructive devices in the human body and as scaffolds for regenerative medicine which utilize tissue engineering. The emerging field of treatment called “regenerative medicine” or “cell therapy” refers to treatments that are founded on the concept of producing new cells to replace malfunctioning or damaged cells as a vehicle to treat disease and injury.

- Drug Delivery Devices

Two photon polymarization also can be utilized for the fabrication of drug delivery devices. These devices enable transdermal delivery of a wide variety of medicinal agents.

Photonics

The ability of 2PP to create complex volumetric structures with exceptionally high resolution makes this technology advantageous for the fabrication of 3D photonic crystals with bandgaps in the visible and near-infrared spectral ranges and fabrication of diffractive optical elements.

Micro Optics

Fabrication of diffractive and refractive micro optical elements, optical waveguides, micrprism arrays and integrated optics.

Micro fluidics

Lab on chip systems, microfluidic device fabrication

Micro Electronic Mechanical Systems (MEMS)

Fabrication of micro and nano MEMS systems.

- Compact and flexible system with different laser options